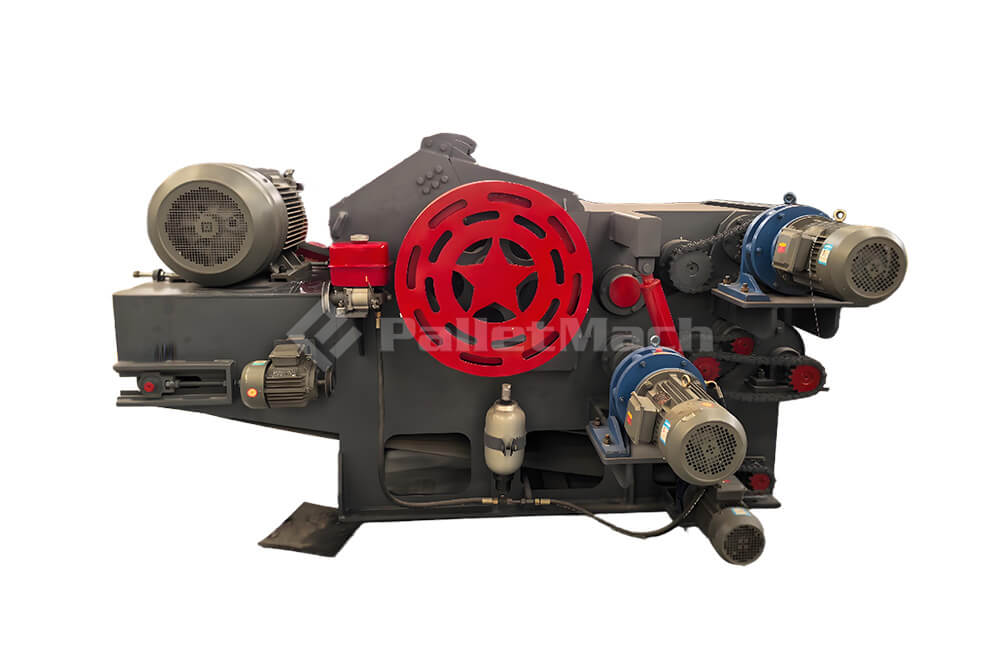

Key features

-

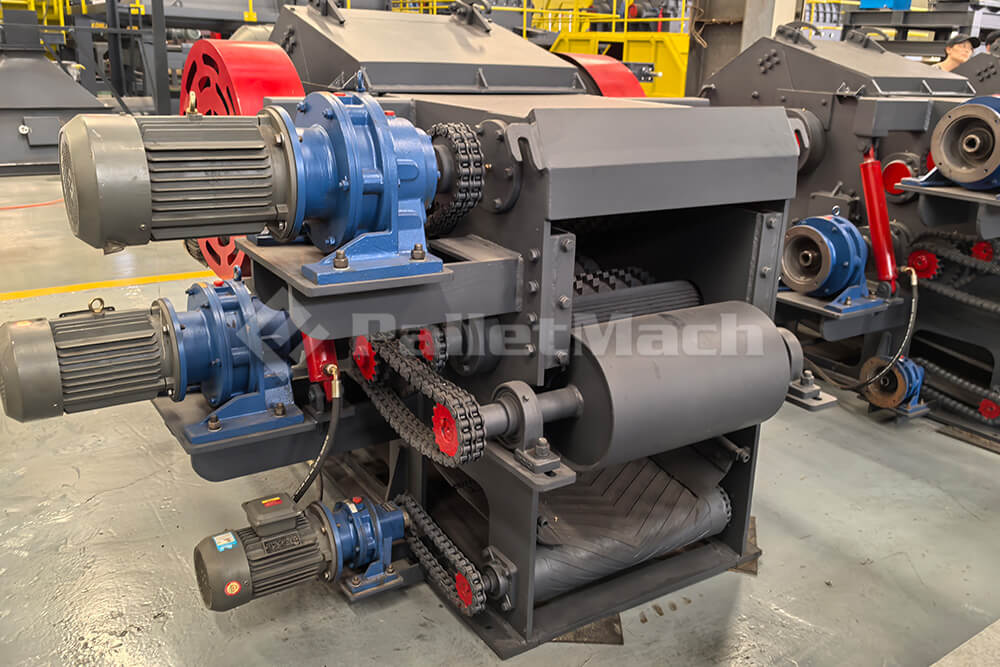

Dual-roller feeding for steady intake and higher throughput — ideal when integrating a drum wood chipper into continuous production lines.

-

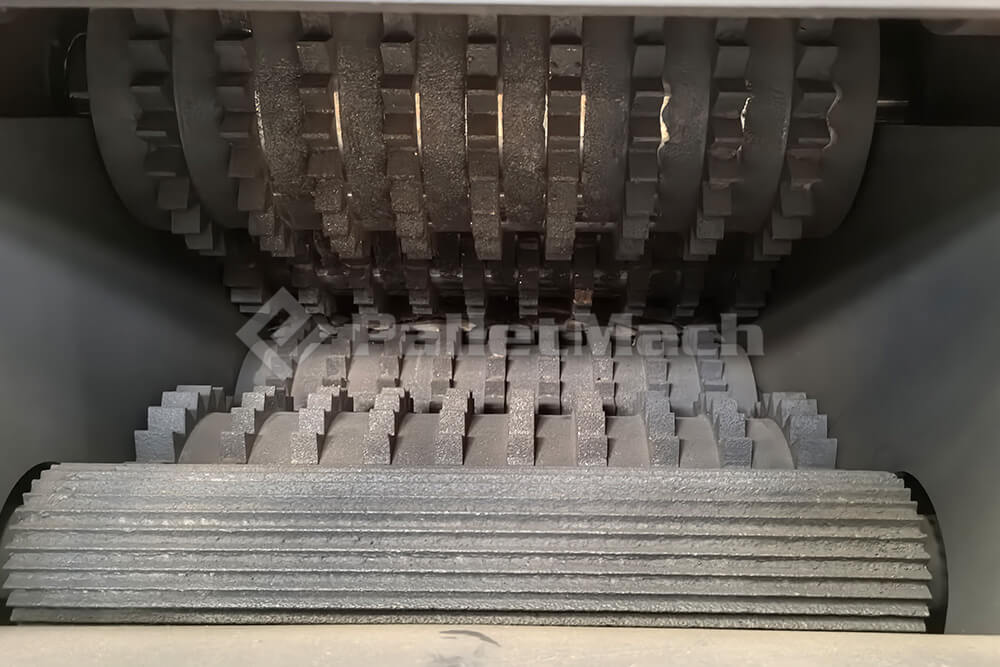

Robust drum rotor & replaceable knives (2/3/4 knife options) — long life and easy maintenance for any industrial wood chipper application.

-

Hydraulic feed & buffer system to process variable diameters and protect against overloads.

-

High-strength steel construction for low vibration and quiet operation.

-

Interchangeable screens for precise control of chip length and thickness — produce chips ready for wood chipper for pallets and other downstream processes.

-

Low noise & shock-resistant body suitable for factory environments.

Applications

Used for: logs, trunks, branches, pallet waste, bamboo, planks, reed, and agricultural residues. Typical end uses include: paper mills, pellet & briquette factories, biomass power/boiler feed, and molded pallet production — a perfect match for the biomass wood chipper role in sustainable energy and material lines.

How drum wood chipper machine works

Material is fed by conveyor and feeding rollers into the drum chamber. High-speed rotating knives shear material against a fixed bed knife; chips that meet the selected screen size pass through the perforated plate and exit the discharge chute. Oversized pieces are recirculated for further chipping until they meet specifications. The hydraulic system manages feed pressure and overload protection to keep the drum wood chipping machine running smoothly.

Benefits — why choose this drum wood chipper

-

Consistent chip quality: uniform length and thickness improve downstream efficiency in pellet mills, paper lines, and molded pallet presses.

-

Higher throughput: dual-roller feed and optimized rotor outperform single-feed designs — a true industrial wood chipper for demanding operations.

-

Versatile feedstock: handles virgin wood, recycled pallets, and a wide range of biomass — perfect as a wood chipper for pallets and mixed feed.

-

Easy maintenance: replaceable knives, accessible rotor, and hydraulic access reduce downtime.

-

Customizable output: screen and knife configurations tailor chips for specific uses (paper, pellets, molded pallets).

Short FAQ

Q: Can this drum wood chipper handle pallet scrap?

A: Yes — configured correctly, the machine functions as an efficient wood chipper for pallets and recycled wood.

Q: Is hydraulic control necessary?

A: Hydraulic feed and buffer are strongly recommended for mixed-diameter materials and to reduce jams in any drum wood chipping machine application.

Q: What are the main wear parts?

A: Rotor knives and screens are the primary wear items; scheduled replacement keeps the biomass wood chipper performing at peak.