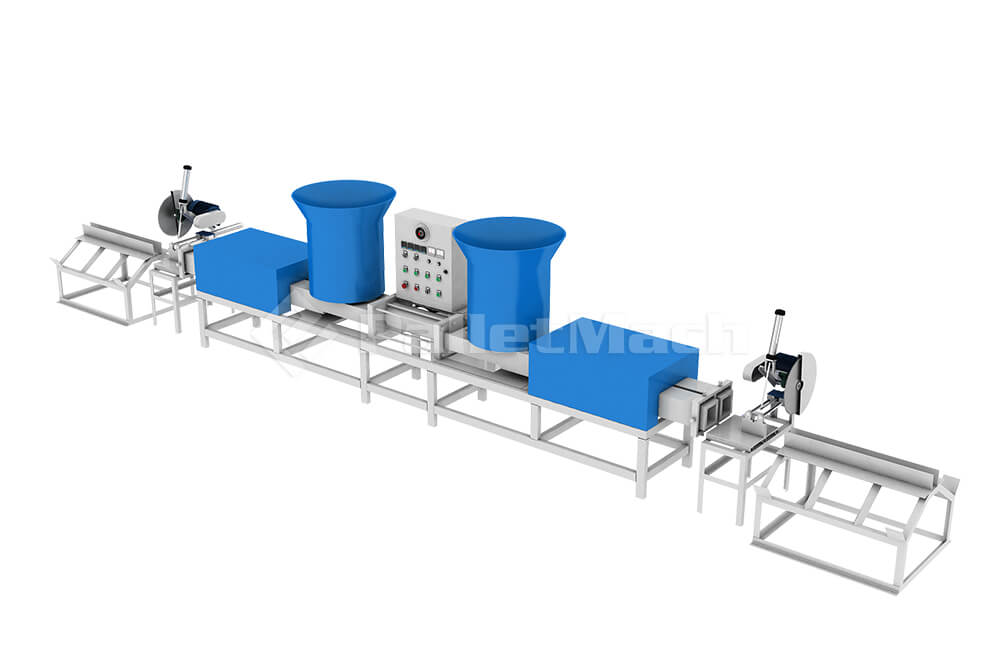

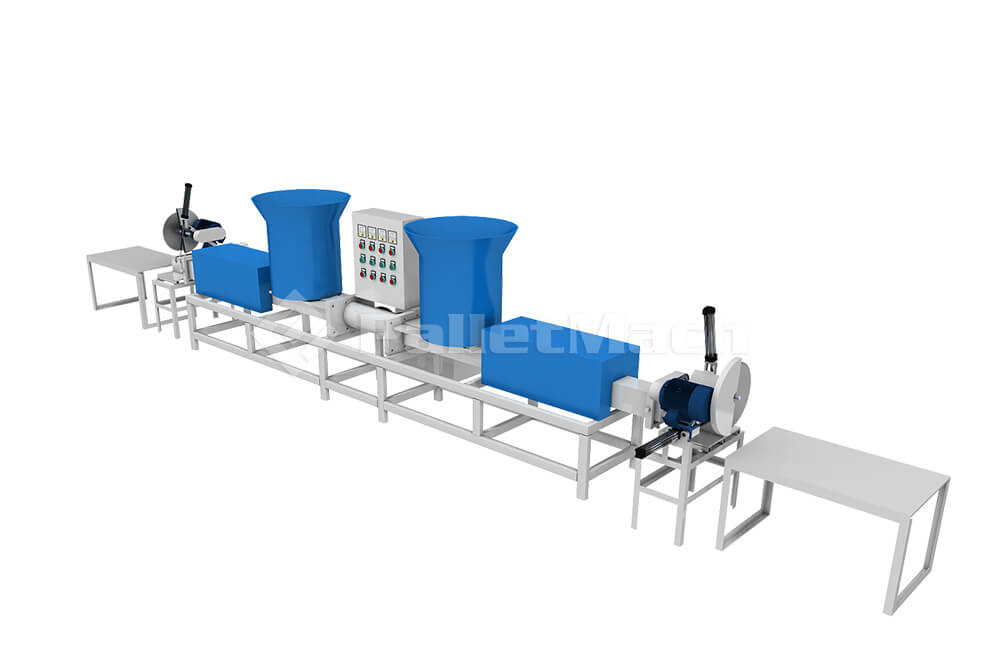

Introduction of double-head pallet block machine

- Double-head wood block machine mainly uses sawdust and wood shavings or other scrap woods as raw materials.

- Double-head wood pallet block machine is mixing with glue in the certain ratio, and extruding mouled pallet block by hot press heating pressure.

- Pressed pallet block machine is the ideal equipment for recycling wood waste.

- The final pressed pallet blocks are free fumigation, and free quarantine. Final pallet blocks are insect prevention, protection against termites and do not easy to burn.

- The capacity of double-head pallet block machine is more than twice as high as the traditional single-head one.

Raw material

Sawdust and wood shavings

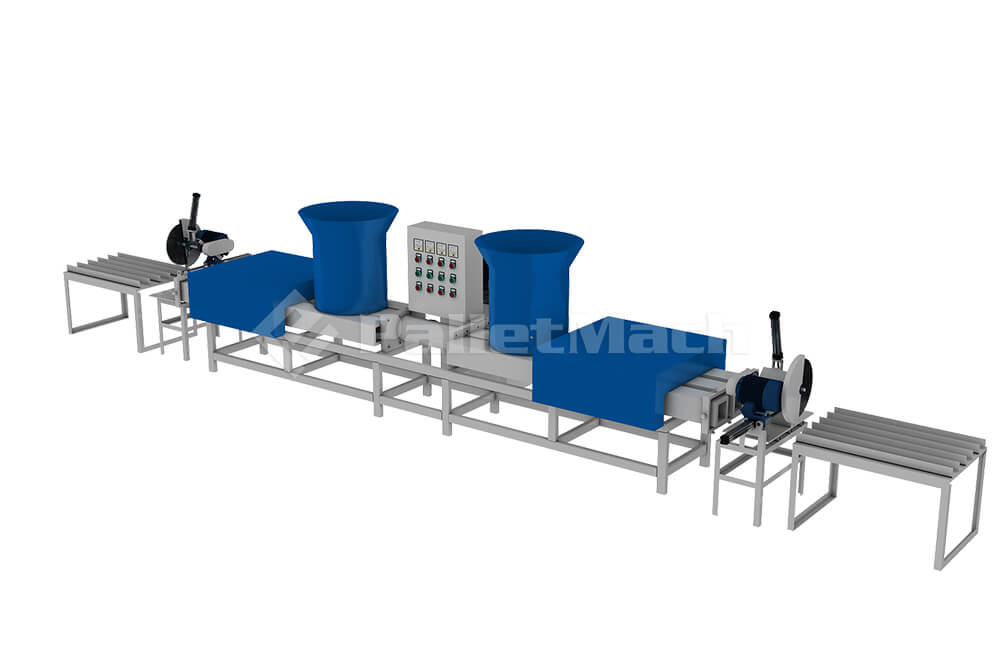

Technology process of pressed pallet block machine

Raw materials → crushing → drying → mixing with glue → hot pressing → long pallet blocks → cutting → final blocks

Final pressed pallet blocks:

- Free fumigation and free quarantine.

- Uniform heating, thorough glue curing, high density, meeting the E1 grade.

- Smooth and clean surface, and good waterproof performance.

- Large load capacity, and easy to nail.